Private label dropshipping feels impossible when you're stuck choosing between brand control and affordable fulfillment solutions.

Private label dropshipping combines branded product ownership with third-party logistics, allowing entrepreneurs to create unique identities without inventory investment. This model has grown 43% annually as businesses seek competitive advantages through custom packaging and branded experiences while leveraging scalable fulfillment networks.

Companies like Dragonfullfil exemplify how modern fulfillment partners enable this transformation through flexible solutions that support brand growth.

How Does Private Label Dropshipping Differ From Traditional Fulfillment Models?

Brand control frustrates many entrepreneurs stuck with generic products lacking competitive differentiation.

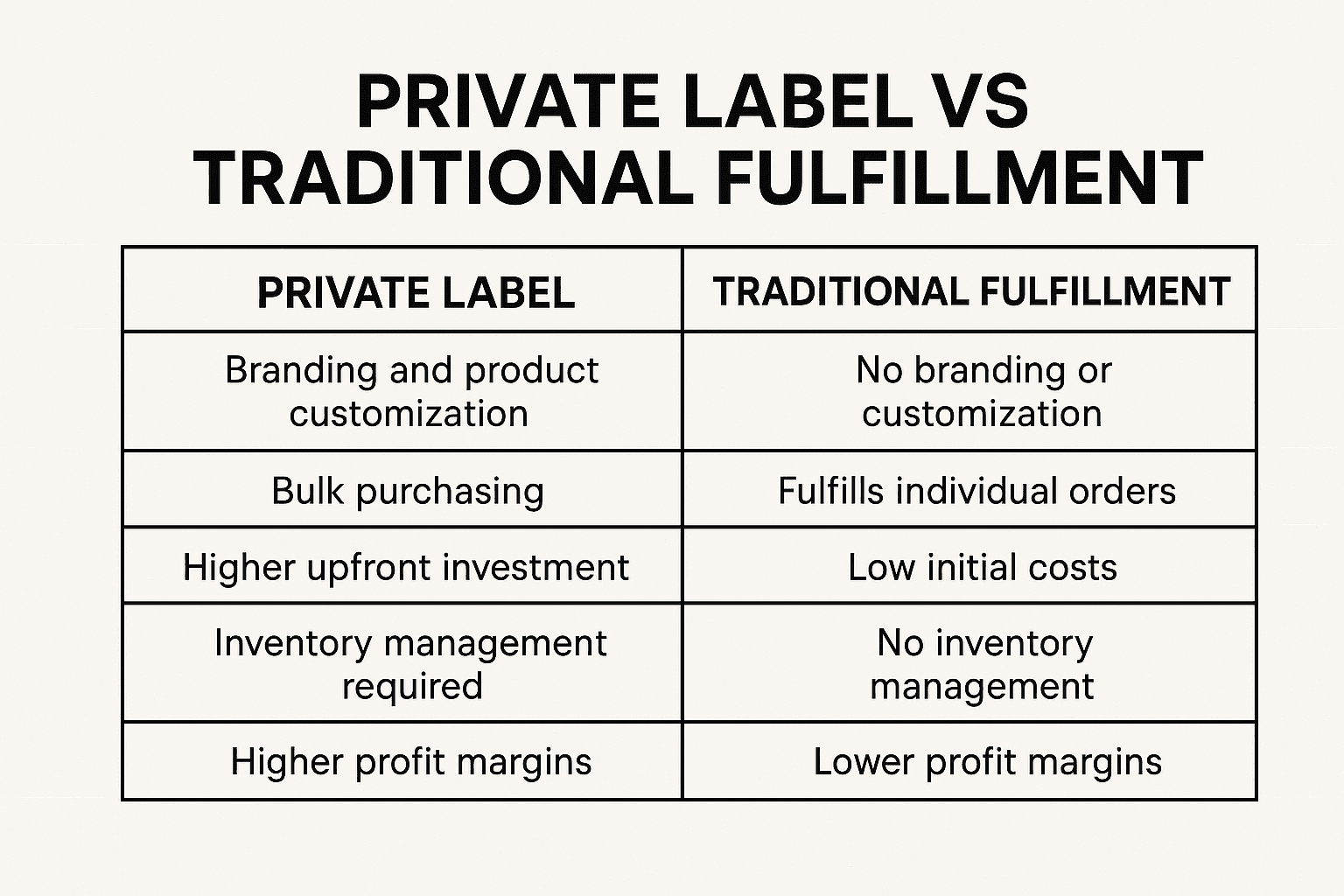

Private label dropshipping combines brand ownership with supplier-managed fulfillment, offering complete packaging control while traditional models require either inventory investment or sacrifice branding authority.

Brand Control and Packaging Customization

Private label fulfillment transforms generic products into branded powerhouses. Unlike traditional dropshipping where suppliers dictate packaging, private label models grant complete control over product presentation. You design logos, choose colors, and craft messaging that resonates with your target audience. This branding authority allows premium pricing strategies that generic products cannot support.

Dragonfullfil exemplifies this approach by offering pre-labeling services and custom packaging solutions that maintain brand consistency across all shipments. Their flexible MOQ requirements enable small businesses to access professional packaging without massive upfront investments.

Profit Margins and Long-term Scalability

Traditional fulfillment models often squeeze profit margins through rigid supplier relationships and limited customization options. Private label partnerships reverse this dynamic by establishing branded product lines with higher perceived value.

| Fulfillment Model | Profit Margin Range | Brand Control | MOQ Flexibility | Packaging Options |

|---|---|---|---|---|

| Traditional Dropshipping | 10-30% | Limited | High | Generic |

| Private Label | 40-70% | Complete | Moderate | Custom |

| Inventory-Based | 50-80% | Complete | Low | Custom |

The scalability advantage emerges through customer loyalty. Branded products foster repeat purchases and referrals that generic alternatives rarely achieve. International shipping capabilities further expand market reach, allowing brands to establish global presence without geographical fulfillment constraints.

What Makes a Private Label Dropshipping Supplier Worth Partnering With?

Finding the right partner can make or break your brand's future growth and customer satisfaction.

Essential private label dropshipping suppliers offer customization options, maintain quality control standards, support low MOQs, and provide comprehensive branding services including custom packaging and pre-labeling capabilities.

Quality Control and Manufacturing Standards

The foundation of successful private label partnerships lies in rigorous quality control processes. Top-tier suppliers implement multi-stage inspection protocols, from raw material verification to final product testing. They maintain ISO certifications, conduct regular factory audits, and provide detailed quality reports. When evaluating potential partners, request samples, review their quality documentation, and understand their defect rate statistics. Reliable suppliers like Dragonfullfil maintain transparent quality metrics and offer batch tracking for complete accountability.

Customization Flexibility and MOQ Requirements

Brand differentiation requires suppliers who accommodate extensive customization options without punitive minimum order quantities. The best private label dropshipping suppliers offer product modifications, custom packaging design, private labeling services, and bundling capabilities. They understand that emerging brands need flexibility during market validation phases. Evaluate suppliers based on their willingness to work with smaller initial orders while scaling production as your business grows.

| Evaluation Criteria | Quality Indicators | Red Flags |

|---|---|---|

| Production Capacity | Scalable systems, backup facilities | Single-facility dependence |

| Communication | 24-hour response time, dedicated account manager | Delayed responses, language barriers |

| Technology Integration | API connectivity, real-time inventory updates | Manual processes, outdated systems |

| Compliance Standards | Industry certifications, regulatory adherence | Lack of documentation, unclear policies |

Conducting thorough due diligence involves verifying business licenses, checking references, and visiting facilities when possible. The right supplier becomes an extension of your brand, ensuring consistent quality and reliable delivery that builds customer trust and supports long-term scalability.

Can Small Businesses Compete Using Private Label Fulfillment Strategies?

Small businesses face the daunting challenge of competing against established brands with deeper pockets and extensive resources.

Yes, small businesses can effectively compete using private label fulfillment strategies by leveraging low MOQ requirements, custom packaging solutions, and flexible branding control to build unique market positions without massive upfront investments.

Breaking Down Traditional Entry Barriers

Private label fulfillment has revolutionized how small business private label operations enter competitive markets. Traditional barriers like high minimum order quantities and complex supply chain requirements no longer prevent startups from launching branded products. Modern fulfillment providers offer MOQs as low as 10-50 units, allowing entrepreneurs to test markets without massive capital commitments.

The flexibility extends beyond quantity requirements. Small businesses can now access professional packaging, pre-labeling services, and international shipping capabilities that were once exclusive to large corporations. This democratization of fulfillment infrastructure enables private label for startups to compete on quality and presentation rather than just price.

Strategic Advantages Through Customization

Smart scaling strategies emerge when small businesses leverage fulfillment partners that understand entrepreneurial needs. Custom packaging becomes a powerful differentiator, transforming ordinary products into premium brand experiences. Dragonfullfil specializes in providing these exact services, offering bundle packaging, custom labeling, and flexible order processing that adapts to growing business demands.

| Strategy Component | Large Business | Small Business Advantage |

|---|---|---|

| Market Response Time | Slow (6-12 months) | Fast (2-4 weeks) |

| Product Customization | Limited by scale | Highly flexible |

| Customer Connection | Impersonal | Direct and personal |

| Innovation Speed | Bureaucratic barriers | Rapid implementation |

The combination of low entry competition barriers and advanced fulfillment capabilities creates unique opportunities for small businesses to establish strong market positions before larger competitors recognize emerging trends.

What Technology Innovations Are Driving Private Label Fulfillment Forward?

Private label brands struggle with outdated fulfillment systems that can't scale. Traditional manual processes create bottlenecks, errors, and customer dissatisfaction. Technology innovation solves these critical challenges.

Advanced fulfillment technology drives private label success through AI-powered inventory management, robotic automation, and seamless integration platforms. These innovations reduce errors by up to 99% while enabling real-time tracking and custom packaging solutions.

AI-Powered Inventory Management Revolution

Modern private label software solutions leverage artificial intelligence to predict demand patterns and optimize stock levels automatically. These systems analyze historical data, seasonal trends, and market fluctuations to prevent stockouts while minimizing carrying costs. AI integration enables real-time visibility across multiple sales channels, allowing brands to maintain perfect inventory balance. Companies utilizing AI-driven inventory management report 15-25% reduction in holding costs and 30% improvement in order accuracy.

Warehouse Automation and Robotics Integration

Robotic fulfillment systems revolutionize private label operations through automated picking, packing, and sorting capabilities. Leading providers like AutoStore and Alert Innovation's Alphabot demonstrate how automation enhances accuracy while reducing labor dependency. These technologies support custom packaging requirements and pre-labeling services essential for private label branding. Automated systems process orders 5x faster than manual operations while maintaining consistent quality standards.

| Technology Innovation | Efficiency Gain | Error Reduction | ROI Timeline |

|---|---|---|---|

| AI Inventory Management | 25% faster processing | 40% fewer stockouts | 6-12 months |

| Robotic Automation | 5x order speed | 99% accuracy | 12-18 months |

| WMS Integration | 30% workflow optimization | 60% fewer mistakes | 3-6 months |

Companies like Dragonfullfil integrate these advanced technologies to provide private label brands with scalable, accurate fulfillment solutions that grow with business needs.

How Are Successful Brands Balancing Quality and Scalability in Private Label Operations?

Private label brands today struggle with maintaining product excellence while rapidly expanding operations. Rising consumer expectations and market competition make this balance increasingly challenging. The solution lies in strategic operational frameworks that prioritize both consistency and growth.

Successful brands achieve this balance through integrated quality control systems, strategic supplier partnerships, and scalable operational infrastructure. They implement tiered quality checks across production phases while building long-term relationships with reliable manufacturers who can grow alongside their business needs.

Strategic Quality Control Implementation

Leading private label brands implement multi-layered quality control systems that scale with production volume. These systems include pre-production approval processes, in-line quality monitoring, and post-production verification. Companies like Target's Goodfellow & Co. maintain consistent quality across thousands of SKUs by establishing clear quality parameters with suppliers and conducting regular audits.

The key lies in creating standardized quality protocols that remain effective regardless of production scale. Brands establish quality benchmarks early and embed them into supplier contracts, ensuring quality consistency from the first order to the millionth unit produced.

Building Scalable Supplier Relationships

| Quality Factor | Small Scale Approach | Scalable Strategy |

|---|---|---|

| Supplier Selection | Single vendor focus | Multi-tier supplier network |

| Quality Control | Manual inspection | Automated systems + audits |

| Communication | Direct contact | Digital platforms + protocols |

| Capacity Planning | Order-by-order | Long-term forecasting |

Smart private label brands develop tiered supplier networks rather than relying on single sources. This approach ensures production capacity can expand without compromising quality standards. Partners like Dragonfullfil provide crucial support through pre-labeling services and quality assurance processes that maintain brand consistency across different production runs and international shipping requirements.

Successful brands also invest in supplier development programs, providing training and resources that align manufacturing partners with their quality expectations and growth objectives.

Conclusion

Private label dropshipping represents the evolution of e-commerce fulfillment, combining brand control with scalable operations. Through strategic fulfillment partners, advanced technology integration, and quality-focused private label strategy, businesses can build distinctive brands without traditional barriers. The future of e-commerce lies in this hybrid model where brand building meets efficient logistics, enabling entrepreneurs to compete globally while maintaining product excellence and customer satisfaction through reliable fulfillment partners.

FAQ

Q1: What are the minimum order quantities for private label dropshipping suppliers?

Most private label dropshipping suppliers offer flexible MOQ requirements, typically starting from 1-50 units per product. Suppliers like Printful and CJDropshipping allow you to start with single orders for testing, while others may require 10-25 pieces for custom packaging and branding. This low barrier to entry makes private label fulfillment accessible for new brand builders without significant upfront inventory investment.

Q2: How long does custom packaging and branding take with private label fulfillment services?

Custom packaging setup typically takes 7-14 business days for design approval and production setup with most private label dropshipping suppliers. Once established, branded products are usually processed and shipped within 2-5 business days. International shipping adds 7-21 days depending on destination. Pre-labeling and bundling services can extend processing time by 1-2 additional days but provide professional presentation for your brand.

Q3: Can private label dropshipping suppliers handle bundling and custom product combinations?

Yes, many private label fulfillment providers offer bundling services where they combine multiple products into custom packages with your branding. This includes creating gift sets, starter kits, or themed bundles. Suppliers typically charge $2-5 per bundle for assembly and custom packaging, making it an effective way to increase average order value while maintaining your brand identity throughout the customer experience.

Q4: What's the difference between private label dropshipping and regular dropshipping?

Private label dropshipping allows you to brand products with your logo, custom packaging, and marketing materials, while regular dropshipping ships products in generic packaging. Private label fulfillment creates a branded customer experience, builds brand recognition, and allows for higher profit margins. However, it typically requires higher MOQs, longer setup times, and additional costs for custom packaging and branding materials.

Q5: Do private label dropshipping suppliers offer international shipping with branded packaging?

Most established private label fulfillment providers offer international shipping while maintaining your custom branding and packaging. They handle customs documentation, duty calculations, and compliance requirements for different countries. International shipping costs typically range from $8-25 depending on destination and package size, with delivery times of 7-21 business days. Some suppliers also offer regional fulfillment centers to reduce shipping times and costs.